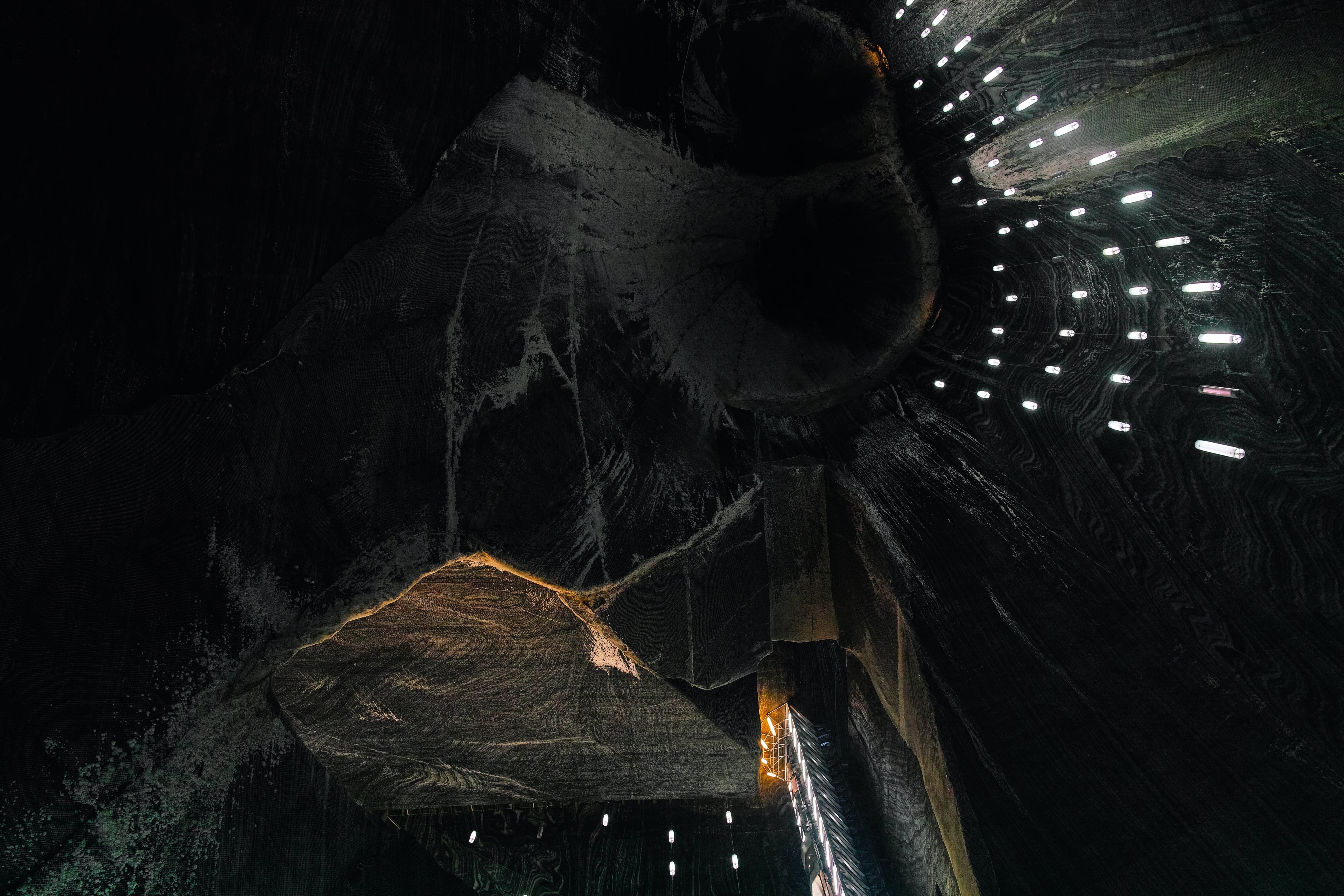

A new technology to counter air quality levels across mines in Western Australia has begun, being described as a ‘virtual canary in the coal mine’.

The original version, actual canaries, were used to detect rising levels of carbon monoxide, methane and other harmful gases right up until the 1980s in Australia.

The trial is understood to be an Australian first. It combines WiFi technology a remotely-operated gas monitoring system, allowing workers to assess safe working levels from the surface of underground mines.

Known as Smart Gas, Perth-based InSig Technologies developed the program, while mining contractor RUC Cementation Mining is trialling it. Co-founder of InSig Technologies explained that the mine had fibre-optic cables throughout which would work alongside the technology to improve worker safety.

“We can now measure the air quality from the surface and we can control fans to provide more or less oxygen as per the demands within the mine.

“We can constantly monitor for things like methane gas and the system will automatically detect if there’s an issue and raise an alarm.”

There are a number of monitoring stations throughout the mine which connect with the surface reader and offer updates to workers, with the system being checked regularly.

The new system allows workers to ensure that sections of mine subject to blasting are clear of residual harmful gases and safe to resume work.

The aim is to roll out the technology to other underground mines across Australia, with around 20 mining incidents a year related to toxic levels of gas or fumes.

Department of Mines, Industry Regulation and Safety (DMIRS) safety director, Andrew Chaplyn said that “it’s important to recognise that in most circumstances, the presence of potentially harmful gas will not lead to injury.”

Michael Nollas, Director at Riklan Emergency Management Services out of Kalgoorlie explained that the benefits of the system go beyond day-to-day work safety procedures at mines.

“If there was an emergency, and they have these sensors strategically placed throughout the mine, from a rescue point of view we would know the gas levels from a fire before we even entered the mine,” he said.

“That’s a massive step forward for the mines rescue industry.”